Subtle Glimpses of the Project.

Farmex Freshia is a premier importer,distributor and manufactruing of high-quality food commodities in the UAE. Specializing in chocolates, dry fruits, and other essential food products, the company oversees a complete value chain from global sourcing to local repackaging and distribution. Known for its uncompromising standards in freshness and quality, Farmex Freshia operates in a dynamic market with stringent regulatory and logistical demands.

Client Location

Dubai, UAE

Industry

Food Import, Repackaging & Distribution, Manufacturing

Tech-Stack

ERPNext Version: 15.61.0

Web Server: Frappe Cloud

Integrations

Amazon

Project Methodology

Agile Scrum Methodology

14

Warehouse

1,300+

SKUs

10+

Van Sales Fleet

11000+

Active Customers

Business Challenges Before ERPNext Implementation

Sajid Sabuwala

CEO

Frustrations:

- No centralized dashboard to monitor inventory, sales, and profitability

- Decisions delayed due to scattered data across departments

Needs:

- Real-time business intelligence and executive dashboards

- End-to-end ERP visibility from import to van sales with a strong ERPNext food distribution focus.

Abdul Salam Shaikh

Plant Manager

Frustrations:

- No system to monitor repackaging efficiency or wastage levels

- Manual logs lead to errors and loss of material traceability

Needs:

- Repackaging cost and wastage tracking

- Batch-wise inventory control for input/output of goods, aligning with modern ERP for food repackaging standards.

Mushtaq Ahmed

Finance Head

Frustrations:

- Sales data from van executives come late and often inaccurate

- Hard to calculate exact landed cost due to lack of systemization

Needs:

- Accurate landed cost calculation and margin analysis

- Integration between van sales, purchase, and accounting

Farmex Freshia grappled with the following issues:

Manual Tracking of Imports

Import shipments, freight bills, and supplier documentation were maintained using spreadsheets and manual processes, leading to delays and errors.

Limited Stock Movement Visibility

Inadequate tracking during repackaging and inter-warehouse transfers negatively affected planning and replenishment, an area where a multi-warehouse ERP system was sorely needed.

Inaccurate Costing

Difficulty in allocating freight, customs, and repackaging costs accurately, resulting in incorrect cost of goods sold (COGS).

Disparate Systems

Sales, inventory, and purchase operations were managed through fragmented tools with no central source of truth.

Regulatory Compliance Gaps

The company struggled to maintain batch-wise traceability and expiry tracking, which are essential for food safety regulations in the UAE.

Inefficient Multi-Warehouse Coordination

Inventory spread across 14 warehouses lacked real-time synchronization, leading to stock-outs or overstocking.

ERPNext Implementation Objectives

In partnership with Sanskar Technolab, Farmex Freshia implemented ERPNext to achieve full operational digitization, laying the groundwork for a transformative Farmex Freshia ERP implementation. Key objectives included:

Process Automation

Automate purchase, inventory, repackaging, and sales workflows.

Accurate Landed Cost Allocation

Allocate freight and customs charges to individual items precisely using Landed Cost Vouchers.

Real-Time Inventory Visibility

Enable live tracking of stock levels across all warehouses through a robust multi-warehouse ERP system.

Full Cycle Automation

Seamlessly automate the flow from Purchase Orders to Goods Receipt, Repackaging, and Sales.

Regulatory Compliance

Implement batch-wise tracking and expiry monitoring to meet food industry standards effectively—an essential component of ERP for food repackaging.

Insightful Reporting

Provide management with actionable dashboards and reports for rapid, data-driven decision-making, key to ERP for supply chain management.

Key Customizations and Enhancements

To meet the unique operational challenges of a competitive food distribution ERP environment, several ERPNext customizations were implemented:

Landed Cost Vouchers

Automated creation from freight and customs invoices, ensuring precise item-wise cost allocation.

Batch-wise Repackaging Workflow

New batch numbers are generated after repackaging, ensuring traceability from raw materials to finished goods.

Multi-UOM Support

Items can be handled and sold in various units such as kilograms, grams, and cartons, supporting both wholesale and retail operations.

Repacking Cost Allocation

Automated calculation of repackaging costs per unit, integrated with item pricing.

Multilingual Print Formats

Custom invoice templates developed in Arabic-English to comply with UAE trade regulations.

Custom Reports & Dashboards

Real-time dashboards for procurement, sales, inventory turnover, and profitability.

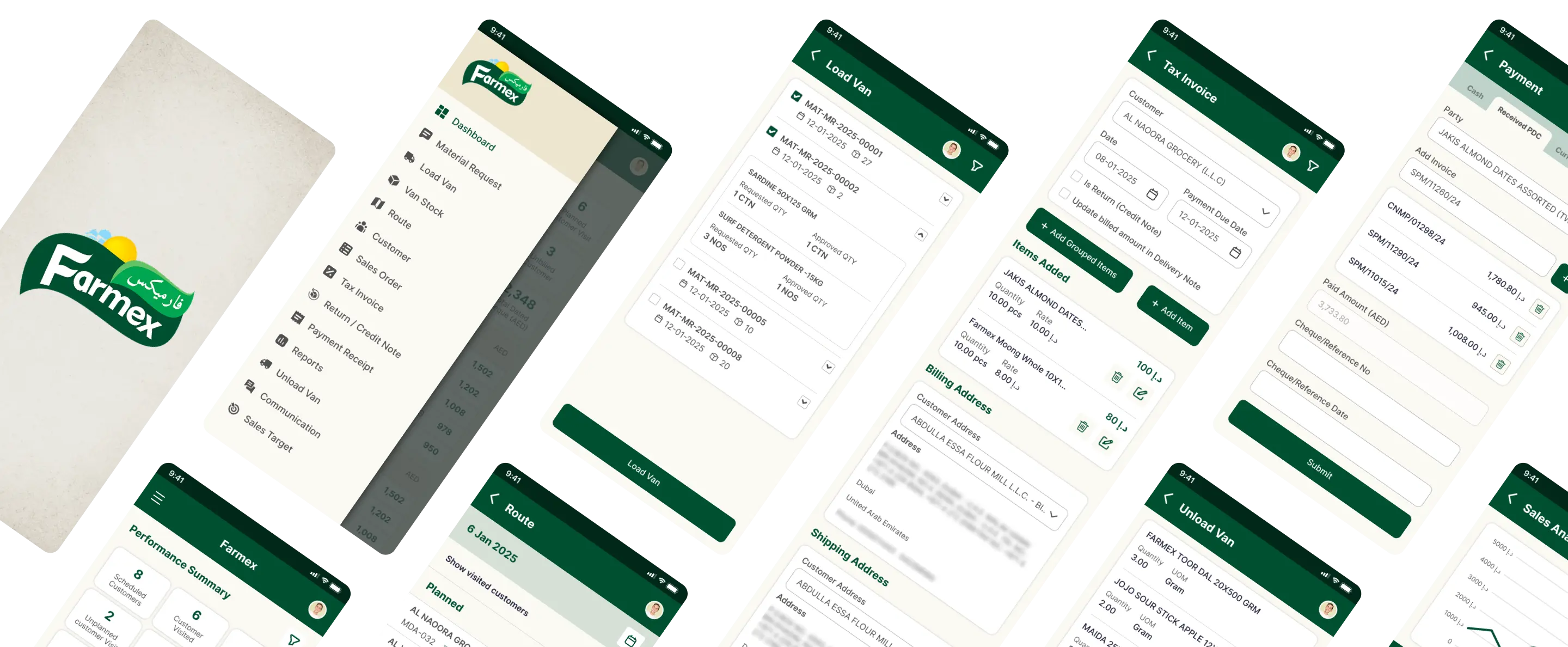

Seamless Van Loading to Unloading All in One App

Dashboard

Material Request

Load Van

Van Stock

Route

Customer

Sales Order

Tax Invoice

Return / Credit Note

Payment Receipt

Reports

Unload Van

Communication

Sales Target

Farmex Freshia’s success story is just one example of how our ERPNext-based Distribution ERP Software transforms FMCG operations. From inventory and repackaging to van sales and real-time dashboards, everything is streamlined in one powerful platform.

Here’s what our client has achieved!

Purchase Import Process

40% Faster

Documentation processing improved significantly.

Stock Visibility

Real-time Tracking

Clear view of raw vs. finished goods across locations.

Repackaging Efficiency

Automated Production

With batch traceability for quality and compliance.

Sales Performance

25% Faster

Order processing with customer-specific pricing logic.

Decision Making

Data-Driven Decisions

Profitability insights and stock alerts for quick decisions.

Feedback from our client!

Farmex Freshia Trading LLC

Implementing ERPNext with Frappe has completely transformed the way we manage our operations. From real-time inventory across 14 warehouses to accurate costing and mobile van sales, everything is now streamlined and transparent. The team at Sanskar Technolab understood our unique challenges and delivered a solution that truly fits our business. We’ve seen a 30% improvement in operational efficiency within the first quarter.

Abdul Salam Shaikh

Plant Manager, Farmex Freshia